Your Soxhlet extraction failed, and you suspect the consumables. A low-quality thimble can tear or contaminate your sample, wasting time, solvent, and your valuable sample.

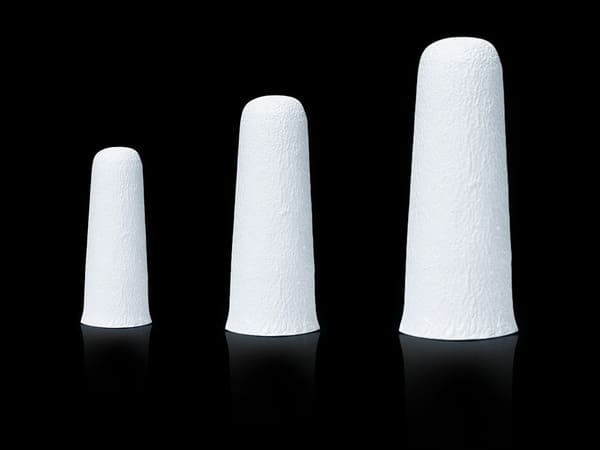

A Soxhlet extraction thimble[^1] is a porous, cup-shaped filter made from materials like cellulose[^2] or glass fiber[^3]. It holds the solid sample inside the extractor, letting the solvent flow through to extract compounds without losing any solid material, ensuring accurate analysis.

I’ve been in the lab filtration business for over 15 years, and I can tell you that this small paper cup is one of the most important parts of the whole extraction process[^4]. The success of your entire analysis can depend on its quality. While it might seem like a simple component, the material it's made from and how it's manufactured are critical. Let's look closer at why this thimble is so important and what you need to know before you buy your next batch.

Why is choosing the right thimble so critical for your analysis?

Are you getting inconsistent or inaccurate results from your Soxhlet extractor[^5]? Your thimble might be causing sample loss or contamination, which can ruin your entire dataset.

The right thimble ensures complete sample containment and purity. Its material must not react with your solvent and must be stable at high temperatures. This prevents contamination and guarantees accurate, repeatable extraction results.

The extraction thimble is the heart of the Soxhlet apparatus. Its main job is to keep your solid sample in one place while the solvent repeatedly washes over it. If the thimble fails, your experiment fails. For example, if the thimble material is weak and tears during extraction, solid particles of your sample will fall into the boiling flask. This contaminates your final extract and makes your results completely invalid. You have to start the entire process over again.

Another critical factor is the purity of the thimble itself. If the thimble is made with binders or contains chemical residues, these impurities can leach out into the solvent. This will artificially inflate the weight of your extracted material, leading to a false high reading. This is why high-quality thimbles[^6] are made from pure materials with no additives. The choice of material is also essential.

Common Thimble Materials and Their Uses

| Material | Best For | Key Features |

|---|---|---|

| Cellulose | Extracting fats, oils, and lipids from food and environmental samples. | Inexpensive and effective for general-purpose extractions with common solvents. Not suitable for strong acids. |

| Glass Fiber | Environmental analysis, stack gas monitoring, and extractions with acidic solvents. | High-temperature resistance (up to 500°C) and excellent chemical compatibility[^7]. Contains no binders. |

| Quartz Fiber | High-temperature testing (>1000°C) and trace element analysis where extreme purity is needed. | The highest purity and temperature resistance. Used for sensitive air monitoring and research applications. |

Are expensive international brands the only option for reliable thimbles?

Do you need high-quality thimbles[^6] but face budget problems and long delays from big-name brands? These issues can stop important projects and create supply chain headaches.

No. Specialized factories like ours in China offer a high-quality, cost-effective alternative. We use the same pure materials and strict quality control to make reliable thimbles without the brand markup or long international delivery times.

As a lab manager or procurement specialist, you know the big names: Whatman, Sartorius, Ahlstrom. These companies make excellent products, and for a long time, they were the only choice for reliable extraction thimbles. But that quality comes with a very high price tag. You are not just paying for the thimble; you are paying for their global marketing campaigns, extensive distribution networks, and the brand name itself. This "brand tax" can significantly inflate your lab's consumable costs.

The problems don't stop at price. Long lead times are a common frustration. Ordering from an international supplier can mean waiting weeks or even months for your products to arrive. And if you need a small batch or a custom size, the situation gets even worse. Many large corporations are not set up to handle small or non-standard orders efficiently. This is where a dedicated factory like HuaEnv has a major advantage. Because we are the manufacturer, we control the entire process. We offer a direct-to-you model that solves these common problems by providing a much more flexible and affordable solution.

How can a specialized factory provide custom thimbles[^8] so quickly?

Do you have a unique project that needs a non-standard thimble size? Big suppliers often quote long lead times and high costs for custom work, which can stop your research.

Specialized factories like HuaEnv control the entire production process. Our in-house engineering and flexible production lines allow us to create custom molds and produce samples for unique specifications quickly, often within just 30 days.

Our ability to be flexible and responsive is one of our greatest strengths. A perfect example of this is a recent project with a client in the United States. The client was developing a new analytical instrument[^9] and needed a very small, custom-sized glass fiber extraction thimble. It was a critical component for their device, and they couldn't find it anywhere on the market.

They approached several large international suppliers first. The response was disappointing. Some said the order volume was too small to consider. Others quoted a development time of over six months and charged very high fees for creating a new mold. Their project was stuck.

Then they found us. After they sent us their specifications, our engineering team immediately started working on a solution. Because we have our own in-house tooling and production lines, we don't have the same limitations as larger companies. We started creating the mold right away. From the initial request to final delivery of the first samples, the entire process took only 30 days. The client was thrilled. They were able to move forward with their instrument development without the long delay and high cost they had expected. This is what a true manufacturing partner can do.

Conclusion

Soxhlet thimbles are critical for accurate analysis. As a specialized factory, we offer high-quality, cost-effective, and customizable thimbles with fast delivery, providing a reliable alternative to expensive brands.

[^1]: Understanding the function of a Soxhlet extraction thimble is crucial for accurate sample analysis. [^2]: Gain insights into cellulose's effectiveness and limitations in various extraction scenarios. [^3]: Understand the unique benefits of glass fiber thimbles for high-temperature and chemical compatibility. [^4]: Get a comprehensive overview of the Soxhlet extraction process to optimize your lab procedures. [^5]: Explore the mechanics of a Soxhlet extractor to enhance your understanding of the extraction process. [^6]: Discover why investing in high-quality thimbles can improve your extraction results significantly. [^7]: Understand the significance of chemical compatibility in selecting materials for lab use. [^8]: Find out how to get custom thimbles tailored to your specific research requirements. [^9]: Stay updated on the latest technologies in analytical instruments that can improve your lab work.