Fan Filter Unit (FFU)

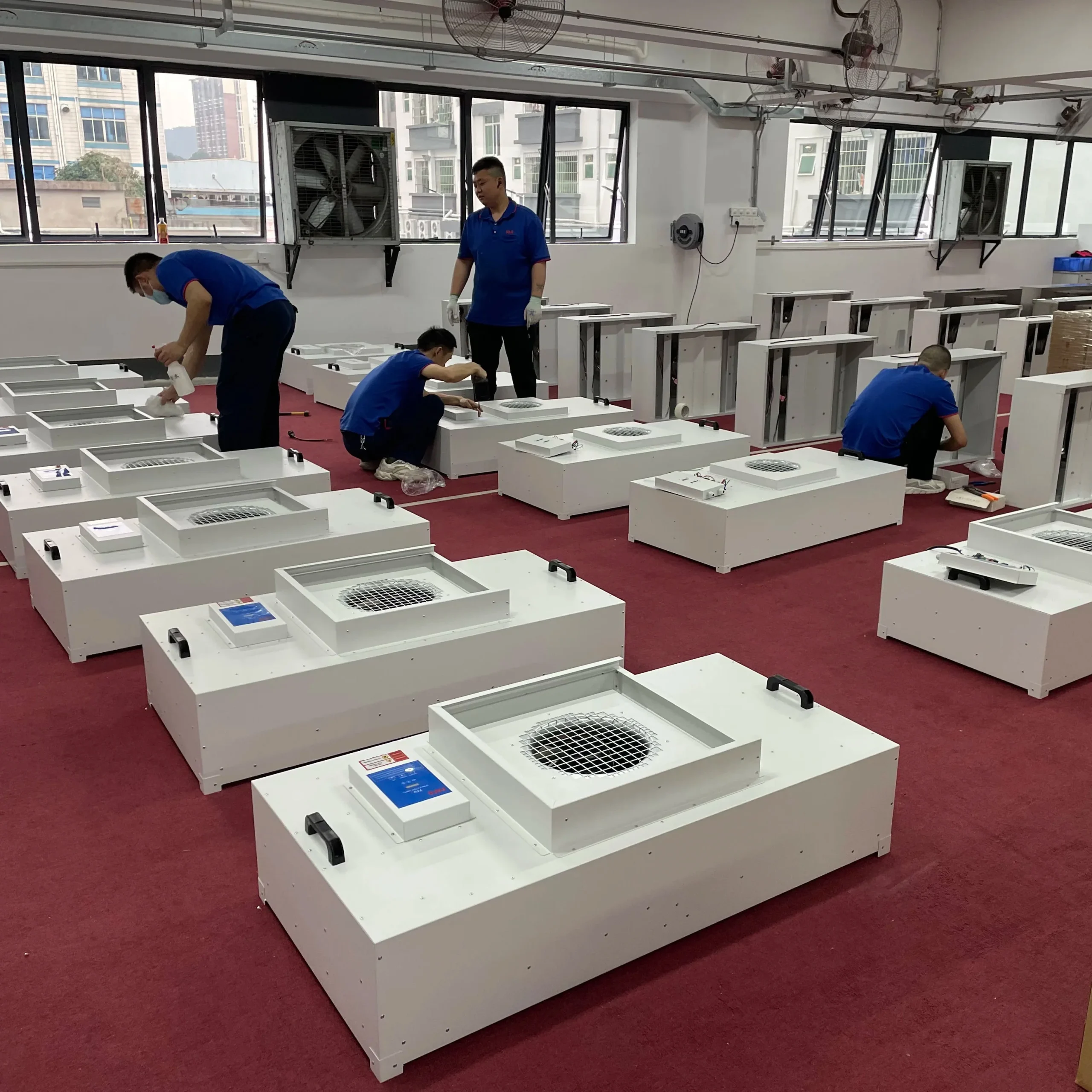

FFU (FAN FILTER UNIT) for clean room

Fan filter unit can be connected for modular application. It is widely applied to clean room, clean bench, clean production line, assembled clean room or partial class 100 clean booth. FFU has both PRE filter and HEPA filter, and it is equipped with air volume adjustable spin-put centrifugal fan which intakes the air from the top of FFU. The clean air will be evenly blown out through the whole air outlet at a wind velocity ranging from 0.35 to 0.6 m/s Material for casing: Cold Rolled steel with powder coated/galvanized aluminum sheet/SUS#201 or 304 Blow fan: AC220V/120V/50HZ/1PH or customized to suit local power supply norms Air velocity: 0.35-0.55 m/s Noise: about 60bBA Optional: Control panel, Remote control, Pre-filter, Pressure gauge

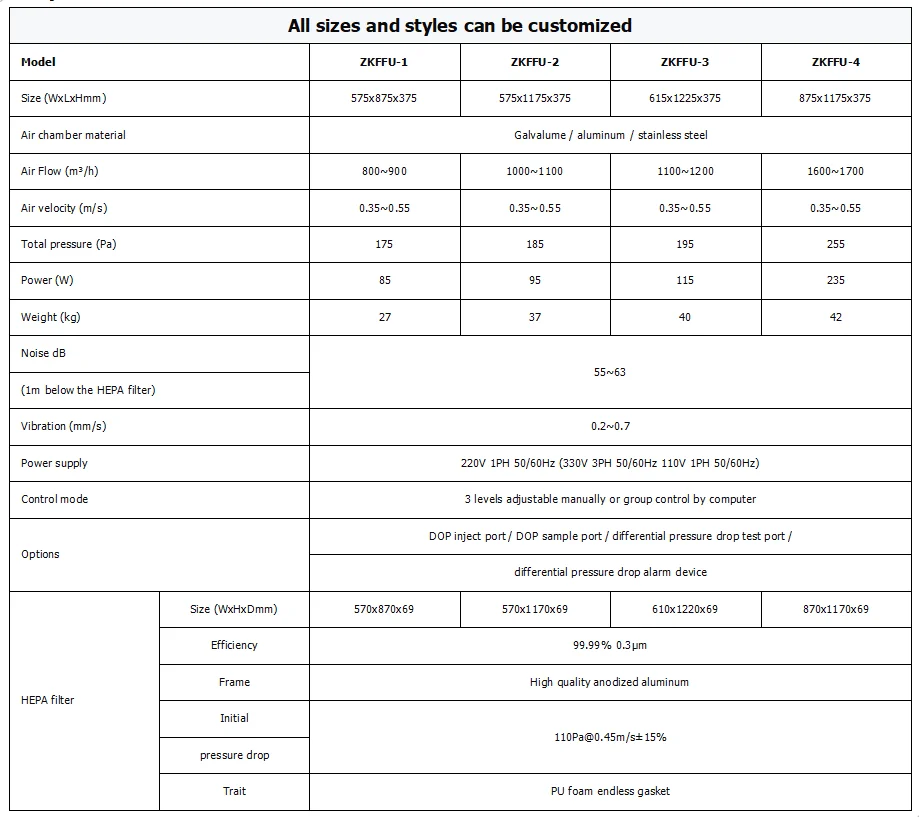

Key Technical Parameters:

Feature

long-life span, low noise, small vibration, adjustable speed.

Can be controlled with thousands of units together.

Control method:

Group control or single control

Fan: AC/EC

Cabinet material:

Cold rolled steel with powder coated / Galvanized

steel/ Aluminum / Stainless steel

Air velocity(m/s): 0.35~0.55

FFU is generator set with motor inside which is used in the turbulent layer and laminar flow clean room. It has characteristic of continuous use. The wind speed can reach 0.45m/s ±20%

Strict monitoring

All FFUs are tested according to the standard of ISO14644-1 before package.

Application

Semiconductor, electron, flat-panel display, disc-drive, manufacture and optics, bio-engineering, clean bench, clean room , or any other places.

Application

High temperature resistant HEPA filter are used in terminal filtration in environments and industries requiring extremely high level of cleanliness, e.g., electronics and semiconductor manufacturing, precision machinery, pharmaceuticals, hospitals, food processing, Beverage Plant etc.